Fatigue Life Analysis for Structures

WINDTECH Consultants analysed the fatigue life for the various key connections within the steel roof fin structure on top of this 300m tall building in the Middle East.

Steel-framed structures can be susceptible to failure through fatigue when small cracks propagate due to repeated loading. This is the case even when this loading is well below ultimate yield strength.

WINDTECH carries out analysis of steel-framed structures to estimate fatigue life given the structures location, form, and orientation. Wind Tunnel testing combined with reliable climatology data will lead to a greater understanding of the effect of wind on structures and ultimately will make more efficient, more reliable structures possible. Load-cycle data can also be provided to enable structural consultants carry out fatigue life studies.

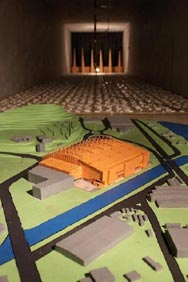

Case Study: 30m high fin on the roof of a 300m tall tower building

This tower building in the Middle East has a 30m high roof fin (refer to the image). The roof fin is of steel-framed construction with welded members and a bolted footing. A fatigue life analysis was carried out for various joint types in the structure. This required an analysis of the local wind climate data and inputs from the structural consultant in terms of the relationship between the applied pressure and the stress experienced at various joints.

A design was presented to ensure the fatigue life of the various joints was satisfactory.

WINDTECH Consultants analysed the load-effect versus number of cycles for a number of key load effects for the steel roof structure.

Case Study: Steel Frame for Forsyth Barr Stadium, Dunedin, New Zealand

This stadium, located in Dunedin, New Zealand was used as part of the 2011 Rugby World Cup. A wind tunnel study was undertaken to determine the design pressures on the structure and cladding for this stadium. The structural loads study was based on the Load Response Correlation technique which has resulted in a light and efficient structure made of ETFE facade and roof cushions supported by a predominantly steel framing structure. The structural consultant engaged WINDTECH Consultants to undertake a load-cycle analysis in the form of load-effect versus number of cycles for a number of key load effects. This in turn was used to undertake a detailed stress-cycle modelling for the connection details associated with these members.

A design was presented to ensure the fatigue life of the various joints was satisfactory.